Request A Quote -

We are located in the Boston area, and work with clients locally and across the U.S. For more information contact owner Sean O'Reilly by using this form or by phone at

(617) 372 5811

Jan 18

0

DMI rHealthX Handheld Sensor

Posted by: Sean

Tags:

Posted date:

January 18, 2015

At 3D Printsmith here in Boston MA, we sometimes need to operate in the dark on a “need to know ” basis when it comes to making 3D printed parts for devices which are proprietary and in development. This can be handled via standard non-disclosure agreement, or simply on a trust basis. It’s more of a challenge, but is a nice feeling to be “behind the scenes” as a new product develops, adding value as we do through fast iterations, advice on design limits for various processes and material requirements, and sometimes acting as a bridge to production or a limited production run of something. When a device is a combination of electronics, physical function or even fluid management, it’s quite astonishing how 3D printing can save time and money without any hard tooling involved. The new reality is that high detail 3D printers all over the world are facilitating prototyping without machining of hard tooling, allowing complex devices to be zoomed into reality at a professional level.

3D Printed X Prize Winner

Recently our behind the scenes feeling turned to all out grins as one of our clients won wide acclaim for a groundbreaking device in healthcare, and we learned that Dr. Eugene Chan and his team at Cambridge based DNA Medicine Institute (DMI) were awarded an X-Prize for their revolutionary “rHealthX” handheld device.

This Could Be the Next Tricorder

This handheld device can sample a single drop of blood in real time, and analyze a patient’s DNA discovering in a matter of seconds whether any of hundreds of medical conditions are present, from the common cold, to exotic infections such as Ebola. Originally developed for monitoring of NASA astronauts, this device is only at the beginning of it’s potential in civilian applications, especially for remote areas without fast access to high level diagnostic laboratories. It’s easy to see how groundbreaking this is, and it is of course a definite nod towards the fictional Start Trek “Tricorder” device which may now one day be ubiquitous thanks to Dr, Chan and his team! Here’s a link to a video clip about the device, and we are very proud to have had a small role in bringing his prototypes forward, congratulations DMI!

Materials, Finishes and Details

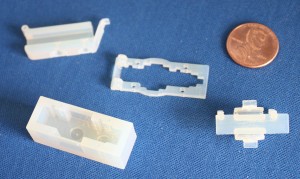

Some challenges with the parts for DMI included achieving parts with both flexibility and toughness for snap fit and latching, and also high detail parts which had very small features. As the limits of small hole sizes are approached for these tiny device parts, design holes can be deliberately undersized and then drilled out to ensure critical dimensions are met. Where finish painting is required, parts need to look as well as molded production parts, and this most often requires some specialized finishing on the parts exterior surfaces. Some parts requiring translucency are used as a visual check of liquid level, and other parts are subjected to chemical cleaning processes which needed to be evaluated for compatibility at the prototype level. All of the above were tackled in the course of making parts for the rHealthX prototypes, and with good success.

Some challenges with the parts for DMI included achieving parts with both flexibility and toughness for snap fit and latching, and also high detail parts which had very small features. As the limits of small hole sizes are approached for these tiny device parts, design holes can be deliberately undersized and then drilled out to ensure critical dimensions are met. Where finish painting is required, parts need to look as well as molded production parts, and this most often requires some specialized finishing on the parts exterior surfaces. Some parts requiring translucency are used as a visual check of liquid level, and other parts are subjected to chemical cleaning processes which needed to be evaluated for compatibility at the prototype level. All of the above were tackled in the course of making parts for the rHealthX prototypes, and with good success.

Learn more at:

DNA Medicine Institute

http://sensing.xprize.org/teams/competition-2-teams/dmi

Navigation Write Us About Us Based in Boston, 3D Printsmith, LLC provides engineering solutions utilizing the latest in 3d printed rapid prototyping, and additive manufacturing technologies. Our team of highly experienced engineers, project managers, designers, and others craft innovative solutions that help you shorten development cycles, reduce costs, and bring better products to market. Our solutions are creative, customized to your needs, and always aligned with your business goals.

-

We serve clients in the engineering R&D, consumer goods, biomedical, energy, architectural and other industries, as well as individual inventors and artists.

Our services focus around 3D printing parts and assemblies, and we are vertically integrated to include 3D CAD modeling, laser or DLP scanning of existing parts into CAD models, post-print surface finishing, and consulting services for additive manufacturing part development .